| |

| |

Dairy production line - Hard and Semi-Hard Cheese Production Lines |

|

| |

|

|

| |

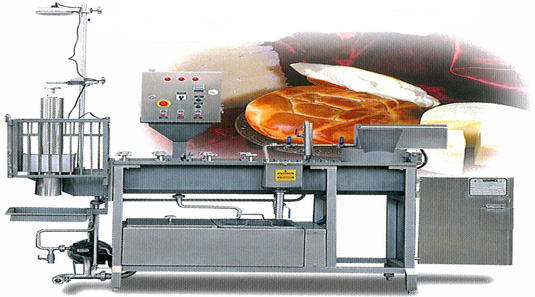

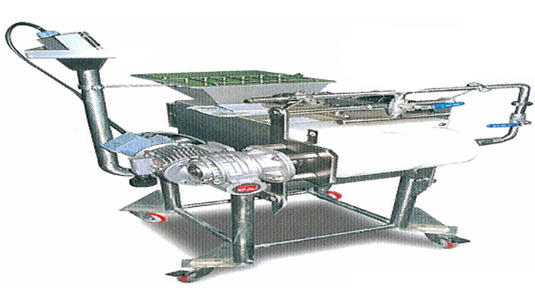

KashaVal & Block Type Mozzarella Cooking Stretching and Moulding Machine (KRMZ)

|

| |

|

| |

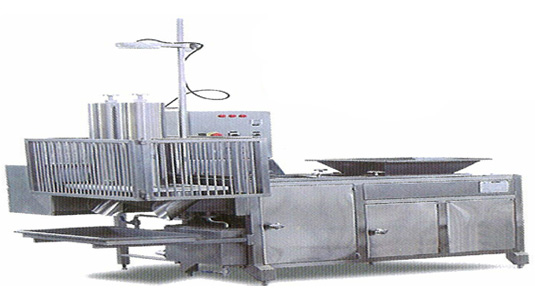

Kashkaval Cooking- Stretching and Moulding Machine (Kr-500)

|

| |

|

| |

Moulding Machine (KR-1000, KR-1500 ,KRMZ-500, KRMZ-1000)

|

| |

|

| |

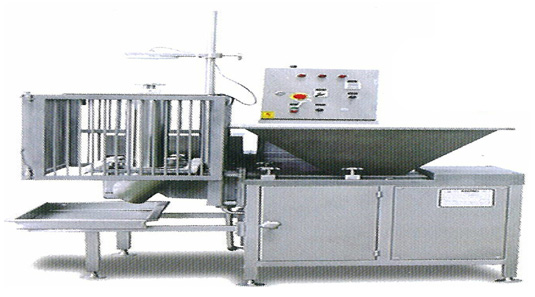

Moulding Machine (KR-500, KR-800)

|

| |

|

| |

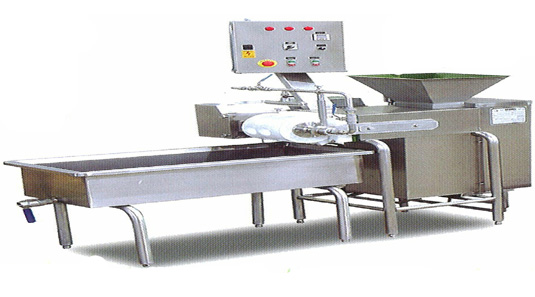

Kashkaval Mozzarella, Tongue Cheese Cooking Stretching and Moulding Machine (KRMZD-01)

|

| |

|

| |

Moulding Machine (KRMZD-01)

|

| |

|

| |

Moulding Machine (KRMZD-200)

|

| |

|

| |

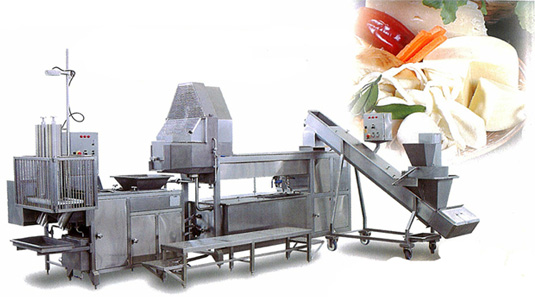

Kashkaval Cheese Production Line

Technical Data

- KR -1500 Kashkaval Cooking – stretching and moulding machine .

- All Types of machine and equipments suitable For semi – Hard and Hard Cheese.

- Possibility to work in mass production and hugenic production.

- It is suitable for semi-hard and Ripcning kashkaval cheese, cheese productions ….

- Kashkaval process Tanks capacity range goes from 1000LT to 8000 LT.

- Coocking –stretching and moulding Machines 300kg / h, 500 kg/h, 800kg/h, 1000 kg/h, 1500 kg/h and 2000 kg/h .

- Electrical systems ( protection grade Ip 65 conforming to the European Standards ) .

- All machines and equipments are built in AISI 304 and AISI 316 stain leas steel and special accessories for food stuffs .

- Entirely built according to the European Regulation CE.

Kashkaval Production Line

- Kashkavel Process Tank

- Rotary Type card Filtered Drum Sifter

- Centrifugal pump

- Pneumatic press

- Cooking – stretching – moulding machine

- Resting Table .

- Vacuum packaging machine

- Shrink Tank

- Moulds washing Basin

- Moulds Hanger

Kashraval process Tanks

Capacity: From 1000 LT to 8000 LT.

Model: Open or closed.

Type: Spherical or 8 Type.

Isolated, Serpentine pneumatic lifting system.

- Accessories :Platform , electrical control panel , CIP inlet , product inlet speed control with inverter or variotor , product out let illumination , sight glass, Air Hole , CIP Mozzles .

- Rotary Type curd Filtered drum sifter with internal circulation system .

- Perforated: Pneumatic press: 300 LT and 500 LT capacities manual press or pane matic press systems.

- Moulds Tost or picnic type, 250gr, 500gr, 1000 gr, 1500gr, 2000gr, and 10 kg or 12 kg capacities.

- Kashraval Resting Tables: Stainless steel or wooden shelves.

- Vacuum packaging machine: Single or Double Covering system.

- Shrink Tank (Electric or steam Heating System).

|

| |

Fresh Mozzarella Cheese Production Line

|

| |

|

| |

Mozzarella Cheese Production Line

Technical Data

All machines and equipments suitable for block type mozzarella and bouel mozzarella production from 1000 LT to 40000 LT/day capacity mozzarella cheese prd.line for both types ( block type or bowl type )

Special Stretching and mounding machines at different capacities for both type mozzarella cheese

Block Type mozzarella stretching and mounding machines

- KRMZ-500, KRM-1000, KRMZ-1500, KRMZ -2000

Stretching and mounding machines

Bowl type mozzarella stretching moulding machines

- KRMZ-50,KRMZ-100 stretching and moulding machines

Production Line

- mozzarella cheese process tank

- Rotary curd filtered drum sifter

- Perforated press

- Mozzarella cooking stretching &mounding machine

- Brine pool

- Plated cooler

- Packaging machine

KRM Z:

-Stretching &mounding machines for block type mozzarella cheese

500 kg/h , 1000 kg/h ,1500 kg/h , 2000 kg/h capacities Stretching &mounding machine, possibility to mould from 0.5 kg up to 2 kg for pizza mozzarella cheese

-All pants in contact with food stuffs are coatedin non-stick ptfe

-Stretching machine, stretching with ougers to allow to give to the product the desired moisture degree by cooking with brine

KRMZ Stretching & mounding machines has Teflon covered hopper basin, direct steam or indirect application on the second stretching section, digital thermometer, electrical panel, circclation pump, special designed transferring system to mounding unit.

KRMZ

-Stretching &mounding machines for boul mozzarella cheese 50kg/15 min , 100kg/15min Capacities stretching & moulding machines,possibility to mould from 10gr. Up to 125 gr. For Bowl mozzarella cheese (fiordilatte )

-All pants in cantact with food stuffs are coated in non-stick ptfe

-KRMZ stretching &moulding mac. Has load Hopper with knife,teffon covered hopper basin , brine water tleating tank with circulation pump, digital ther mometer , electrical panel, circulation pump, special designed moulding drum .

-Moulding machine, after stretching of product, the curd in trouns feared to the moulding dram by manually, possibility to mould very quick by ougers fecding

-KRMZ –Harding vat is entirely made of AISI 304 S_S and materials for food stuffs, 800 kg product / h capacity.

It has modlular cheese tanks porting patane, extraction belt, circulation pump, plated cooler,….. |

| |

| |

|

|

| |

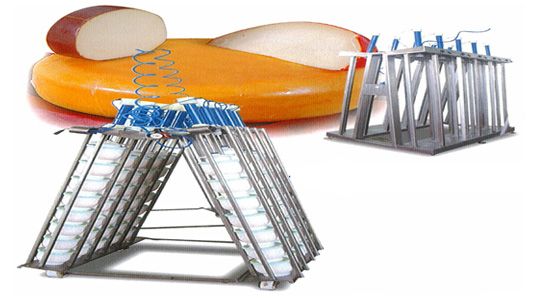

Gouda & Edam Cheese Press

|

|

| |

|

|

| |

Gouda & Edam Cheese Production Line

Technical Data

- From 5000 LT/day to 20000 LT/day capacities complete production line.

- Special design process tank ( 1000 LT-8000LT ) capacity

- 300 kg – 500 kg in different capacities Pneumatic presses

- Special Ripening Trolleys

- Brine systems according to total daily capacities

Production Line

- Process Tank.

- Prenmatic Perforated Pre-press

- Gouda &Edam pres

- Brine Heat exchanger

- Brine Pool

- Trolley

- Ripening Shelves

- Paraffin machine

Gouda & Edam Process Tanks

Capacity: From 1000 LT to 8000 LT

Model: Open or Closed

Type: Spherical or 8 Type

Isolated: Serpentine, pneumatic lifting system

Accessories

Plat form, decterical control panel, CIP inlet, product inlet, speed control with inverter or product outlet, illumination, sight Glass, Air tlofe, CIP Nozzles

Technology

Pneumatic press that works by air connection (300 kg & 500 kg) capacity

Gouda press: 5 shelves, pneumatic pressing system, manual control, ergonomic design

The capacity of Gouda &Edam press can change according to Gouda &Edam mould’s dimensions

Brine pool: AISI 316 S.S Structure, 1500 LT - 3000 LT- 4000LT capacities

Cooling water system: cir collation pump |

|

| |

|

|

|

|