| |

| |

Meat production line |

|

| |

|

| |

This project is prepared according to sausage –salami establishment for

ASHRAF AGRICULTURAL P.L.C.

THE PROJECT OF INSTALLATION 20.000 KG/DAY PRODUCTION OF SAUSAGE- SALAMIS ESTABLISHMENT

INTRODUCTION

After company authorized person Mr. Cengiz KABADAY invitation, as aresult of our visit to your sausage –salami establishment at 25-May – 2009,

We determined necessary machine and equipments to provide desired capacity of establishment. The project in below is prepared according to experiments by our engineers.

List OF NECESSARY MACHINES AND EQUIPMENTS

- KRT 500 MIXING MACHING

- CTR 300 CUTTER

- JAMBON MOLD

- ICE MAKER 1600 KG/DAY

- DKM 200 FROZEN & FRESH MEAT MINCING MACHINE

- SAUSAGE FILLING TABLE

- DED-1000 FROZEN MEAT CHOPPING MACHINE

- SMOKE GENERATOR

- FPK 400 OVEN WITH 2 TROLLEYS ( smoking , cooking , drying )

- VP 600 VACUUM PACKING MACHINE

- VP 1000 VACUUM PACKING MACHINE

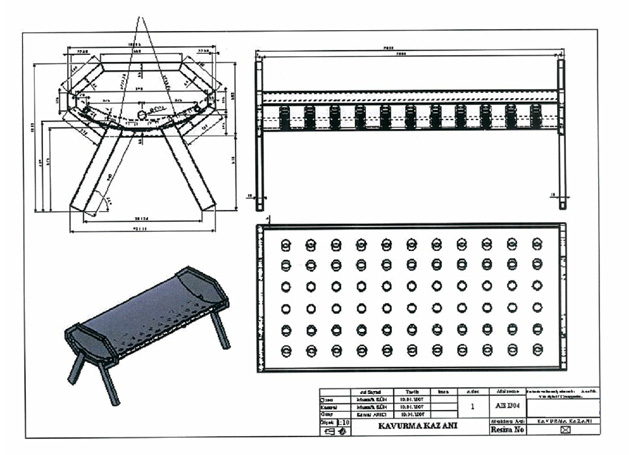

- ROAST MEAT BOILER MACHINE

- SAUSAGE PEEL MACHINE

- AUTOMATIC AUTOCLAVE

- OKM 34100 AUTOMATIC CLIPS MACHINE

- ODM 100 AUTOMATIC FILLING MACHINE

- CONSERVE BELT CONVEYOR

- CONSERVE SEAMER

- FILLING MACHINE FOR CONSERVE PRODUCTION

- MEAT CARRIER

- OVEN TROLLEY

- SHRING MACHINE FOR CONSERVE

- ( HOT ) SHRING MACHINE FOR MEAT

LIST OF MACHINE AND EQUIPMENTS ESTABLISHMENT HAS

- MEAT PROCESSING TABLE

- FROZEN MEAT CHOPPING MACHINE

- MODEL 130 MEAT MINCING MACHINE

- EMULSIFIER MACHINE

- CTR 120 CUTTER

- BOILER FOR SALAMIS

- PACKING MACHINE

- MEATBALL FORMING MACHINE

PRODUCTION PER ONE DAY:

4 Tons conserve (salami)

1.5 Tons Roast boiler meat

1.5 Tons sausage

4 Tons Turkish sausage

6 Tons salami with casing

1 Ton Hamburger

600 kg Jambon |

| |

NUM |

PCS |

DESCRIPTION |

1 |

1 |

KRT500 MIXING MACHINE |

2 |

1 |

CTR330 CUTTER |

3 |

100 |

JAMBON MOLD |

4 |

1 |

ICE MAKER 1600 KG /DAY |

5 |

2 |

DKM 200 FROZEN 7& FRESH MEAT MINCING MACHINE |

6 |

3 |

SAUSAGE FILLING TABLE |

7 |

1 |

DED-1000 EROZEN MEAT CHOPPING MACHINE |

8 |

3 |

SMOKE GENERATOR |

9 |

4 |

FPK400 OVEN WITH 2 TROLLEYS (Smoking , Cooking , Drying ) |

10 |

1 |

VP 600 VACUUM PACKING MACHINE |

11 |

1 |

VP 1000 VACUUM PACKING MACHINE |

12 |

2 |

ROAST MEAT BOILER MACHINE |

13 |

1 |

SAUSAGE PEEL MACHINE |

14 |

1 |

AUTOMATIC AUTOCLAVE |

15 |

3 |

OKM 34100 AUTOMATIC CLIPS MACHINE |

16 |

3 |

ODM 100 AUTOMATIC FILLING MACHINE |

2 |

FILLING MACHINE 200LT |

CONSERVE PRODUCTION LINE |

17 |

2 |

CONSERVE BELT CONVEYOR |

18 |

2 |

CONSERVE SEAMER |

19 |

2 |

FILLING MACHINE FOR CONSERVE PRODUCTION |

THR OTHER PRODUCTION EQUIPMENTS |

20 |

50 |

MEAT CARRIER |

21 |

33 |

OVEN TROLLEY |

G |

1 |

AUTOMATIC PACKAGING MACHINE |

22 |

1 |

SHRING MACHINE FOR CONSERVE |

23 |

1 |

( HOT ) SHRING MACHINE FOR MEAT |

|

| |

|

| |

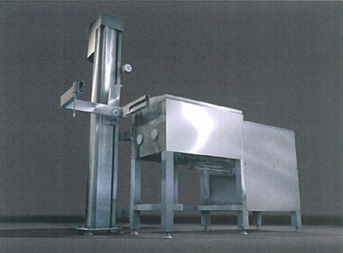

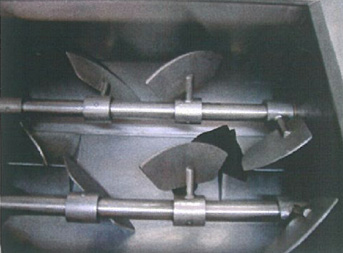

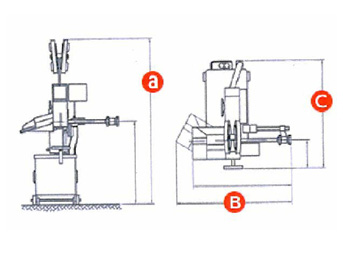

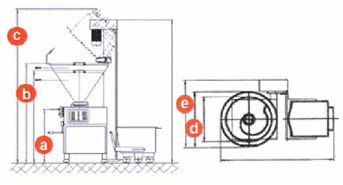

1- Model KRT 500 Mixing machine |

| |

HYGIENIC – EASY TO CLEAN – SIMPLE TO USE

Used in sausage, spiced sausage, salami, doner kebab, meat ball production and in the meat processing industry. Ensures that the product and spices and other ingredients are mixed homogenously thanks to the interlacing pallets within the reservoir.

The product reaches the desired consistency within a maximum of 10-15 minutes.

Vacuuming, heating and cooling system

could be added optionally at larger capacities. |

|

- Equipped with a powerful engine and gearbox system.

- With safety switch.

- Equipped with a lift at larger capacities.

- Entirely made up of 304 quality stainless metal.

- Hygienic.

- Extremely easy and simple to clean.

- Very easy and simple to use.

- Wholly conforms to CE directives.

|

|

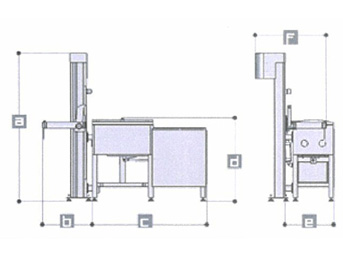

KRT500 Dimensions |

A |

2705MM |

B |

894MM |

C |

2438MM |

D |

1700MM |

E |

1200MM |

F |

1291MM |

|

|

Model |

KRT 500 |

Machine category |

Mixing machine |

Capacity kg/h |

350 |

Engine power |

7 |

Net Weight kg |

1130 |

|

|

| |

|

| |

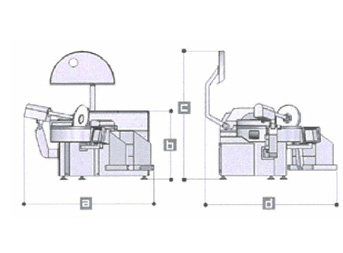

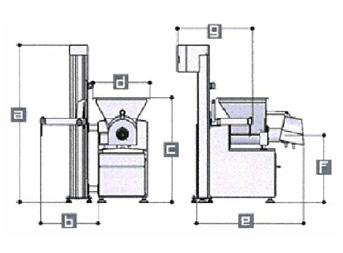

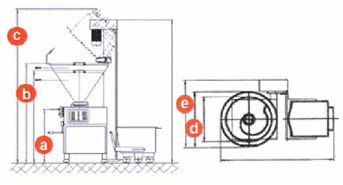

2- MODEL CTR 330 Liter Cutter |

| |

HYGIENIC – EASY TO CLEAN – SIMPLE TO USE

Vessels and frames of all models are made up of 304 quality stainless chromium. They could be equipped with double revolution or speed control apparatus (with frequency convertor) as desired. Models with frequency convertor are capable of emission and to increase/decrease the engine rate.

4 or 8 European blades are used. Ctr-200 and ctr -300 could be equipped with optional loading apparatus.

The loading and unloading system is hydraulic. The operator panel is equipped with a graphic display and 25 programs.

Internal and external temperatures could be monitored from the display. Hygienic. Easy to maintion and mount. |

| |

|

| |

- Entirely made up of 304 quality stainless metal.

- Hygienic.

- Extremely easy and simple to clean.

- Wholly conforms to CE directives.

- Very easy and simple to use.

|

| |

Model |

CTR 300 |

Machine category |

Cutter |

Capacity kg/ h |

1300 |

Engine power/ kw |

90 |

Net Weight kg |

4000 |

|

| |

Technical informations

Ctr330 Dimensions/mm |

A |

2675 MM |

B |

1410 MM |

C |

2646 MM |

D |

2695 MM |

|

|

|

| |

|

| |

3- JAMBON MOLD

|

| |

|

| |

4- ICE MAKER 1600 KG/ DAY |

| |

ELECTRICIAL REQUIREMENTS: 3ph- 380V-50HZ

16 C 25 C

STANDART CONDITIONS: Water temp. 16 c, Ambient tempo.

25 C, 5 C -40 C 0C- 40 C,

ACCEPTABLE CONDITIONS: ambient temp. 5c-

40 c, water temp.

0C -40 C, -1.5-2.2MM

ICE THICKNESS: -1.5-2.2MM

COOLING AREA: R717 R22 R404A

Generally used on big scale ice production. |

|

|

| |

|

| |

5-MODEL DKM 200 FROZEN & Fresh Meat Mincing Machine HYGIENIC – EASY TO CLEAN – SIMPLE TO USE |

| |

Used in sausage, spiced sausage, salami production and the meat processing sector and in particular in mincing meat subjected to shock at -40c.

- Ensures that the flesh and bones of chicken, turkeys and fish come out of the machine separately thanks to the optional and specially designed separator system.

- Equipped with mirror and blade system used in frozen meat mincing machines at EU standards.

- Optional sinew separator system

- Equipped with a powerful engine and gearbox system.

- With two helixes for fresh and frozen meat.

- Double- revolution.

- With Lift.

- Capacity of 250 it. Of meat.

- Entirely made up of 304 quality stainless metal,

- Hygienic.

- Extremely easy and simple to clean.

- Wholly conforms to CE directives

- Very easy and simple to use.

|

| |

|

| |

Technical Specifications |

| |

Model |

Dkm 200 |

Machine category |

Fresh and frozen meat grinder |

Capacity kg/ h |

4000-2000 |

Engine power/ kw |

30/48 |

Net Weight kg |

1870-2100 Net weight with separator system |

|

| |

Technical informations

DKM 200 Dimensions/mm |

A |

2705 MM |

B |

996 MM |

C |

1798 MM |

D |

985 MM |

E |

1847 MM |

F |

1152 MM |

G |

1291 MM |

|

|

|

| |

|

|

| |

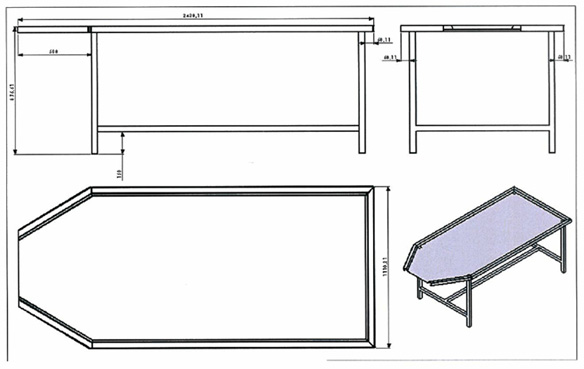

6- SAUSAGE FILLING TABLE |

|

| |

|

|

| |

|

|

| |

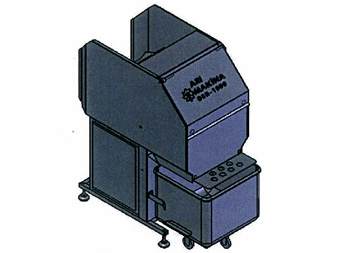

7- MODEL DED-1000 FROZEN MEAT CHOPPING MACHINE |

|

| |

Technical Specifications

- Entirely made up of 304 quality stainless metal.

- Hygienic.

- Extremely easy and simple to clean.

- Wholly conforms to CE directives.

- Very easy and simple to use.

|

|

|

|

| |

Model |

DED-1000 |

Classification |

Frozen meat chopping machine |

Capacity kg/ h |

1000 |

Engine power/ kw |

2.2 |

Net Weight kg |

600 |

|

|

| |

Working pressure bar 6 |

|

| |

Dimensions/mm |

DED-1000 |

W |

745 |

L |

1600 |

H |

1720 |

|

|

| |

|

|

| |

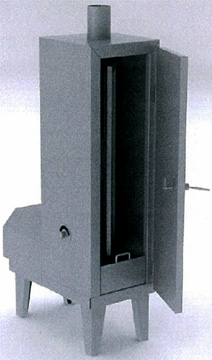

8- SMOKE GENERATOR |

|

| |

|

|

| |

|

|

| |

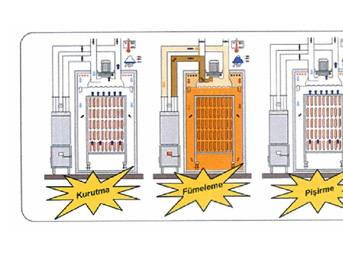

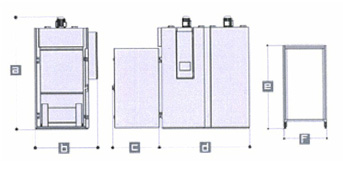

9- MODEL FPR 400 Ovens |

|

| |

(SMOKING – COOKING – DRYING) HYGIENIC – EASY TO CLEAN – SIMPLE TO USE |

|

| |

Used in sausage, spiced sausage, salami, doner kebab, meat ball production and to smoke fish.

Capable of cooking boiling, frying and smoking.

The heating system could be steam, electric,with boiler

(natural gas or diesel fuel as desired. Easy to use and program thank to the full-automatic electronic board.

Equipped with a thermometer to automatically read and

Transmit the wet, dry and humid temperatures.

Comes with a printer outlet for quality control purposes.

Air-condition system could be added optionally.

Models with 1.2 and 4 trolleys are standard and

special ovens could be manufactured on demand. |

|

|

|

| |

STEAM GENERATOR AND SYSTEM ARE NECESSARY FOR OVEN. 750 kg /h 6 bar |

|

| |

Technical informations

Model |

FPK 400 |

Machine category |

Oven (SMOKING -COOKING – DRYING) |

Capacity kg/ h |

800 |

Engine power/ kw |

8 |

Net Weight/ kg |

1500 |

|

|

|

|

| |

Machine Dimensions/mm |

A |

2959 MM |

B |

1697 MM |

C |

1234 MM |

D |

2386 MM |

E |

1938 MM |

F |

1000 MM |

|

|

|

|

| |

|

|

| |

10- MODEL VP-600 Vacuum Packing Machine |

|

| |

HYGIENIC – EASY MAINTANANCE – EASY INSTALLATION |

|

| |

Used in cheese, meat, chicken, spiced sausage, salami etc. packing. Entirely made up of 304 quality stainless steel. Extremely easy and simple to clean. Hygienic. Digital panel, sealing and cooling time. Wholly conforms to CE directives |

|

|

|

| |

VP 600 Technical Specifications |

|

| |

| Model |

VP 800 |

| Vacuum Pump |

Busch |

| Pump Capacity |

40m3/h |

| Electricity consumption |

1.1 kw Threephaze 230/400V-50-60 Hz |

| MAP |

Available |

| Net Weight kg |

140 kg. |

|

|

| |

|

|

| |

11- MODEL VP-1000 Vacuum Packing Machine |

|

| |

HYGIENIC – EASY MAINTANANCE – EASY INSTALLATION |

|

| |

Used in cheese, meat, chicken, spiced sausage, salami etc. packing. Entirely made up of 304 quality stainless steel. Extremely easy and simple to clean. Hygienic. Digital panel, sealing and cooling time. Wholly conforms to CE directives |

|

|

|

| |

VP 1000 Technical Specifications |

|

| |

| Model |

VP 1000 |

| Vacuum Pump |

Busch |

| Pump Capacity |

100m3/h |

| Electricity consumption |

2.2 kw Threephaze 230/400V-50-60 Hz |

| MAP |

Available |

| Net Weight kg |

240 kg. |

|

|

| |

|

|

| |

12- ROAST MEAT BOILER

|

|

| |

|

|

| |

13- SAUSAGE PEEL MACHINE

ENTIREL MADE UP OF 304 QUALITY STAINLESS STEEL

PEEL PROCESS WORK SERIES

CONTROL OF SPEED

OPTIONALLY STEAM UNIT |

|

| |

|

|

| |

14- AUTOMATIC AUTOCLAVE |

|

| |

TAM AUTOMATIC AUTOCLAVE 4A2750 OMS4AUTO2750

(ø 1400 × 4 baskets)

It is completely manufactured of AISI 304L quality stainless steel.

It is isolated with exterior rock wool and covered with sheet steel.

PLC system controlled and operated. It is coupled with Alfa Laval plate heat exchanger in order to minimize water consumption and chemical use machine. Spray system used in our machine is performed by the nozzles produced specially and the water is pulverized and so the temperature required is provided at maximum level everywhere in the machine.

All of the controls and input such as the pressure, air, water vapor and level as well as touch screens PLC display are designed at outside of the main panel on the machine in order to make user's control easier.

It is operated and controlled with a program specially made by OSMANLI MAKINA for our full automatic autoclaves. The pressure and temperature is recorded at the main panel by a roll for system control and recording.

The machine cover gasket system is air type; thus, the gasket change becomes minimum.

The system safety is controlled electrically, pneumatically and mechanically at the same time.

1.1a AUTOCLAVE BASKET 8 Pcs

It is completely manufactured of AISI 304 stainless steel. 980x980x920mm

1.1b AUTOCLAVE CARRIAGE 8 Pcs

It is manufactured of iron material. It is painted

1.1c

The basket guider is manufactured of Inoxs material. 1 Pcs

Some of other specifications which our machines have but the equivalent machines do not have:

- It complies with CE certification and procedure (the project, electrical & electronic parts, valves, and all other production).

- PLC control and operating panel has a touch screen display (LG).

- Memory-card recorder. (512 Mb) ABB.

Alfa Laval Plate Heat Exchanger (To minimize internal water change and decrease chemical use).

Furthermore, the heat exchanger eliminates sudden pressure decreases and it is very important for the system.

- Spraying system is provided by specially produced pulverizing nozzles and spraying is made from 5 positions.

- Cover gasket is air-pusher and a continuous friction does not exist in order to not allowing gasket wearing.

- The used air, vapor, water and release valves are rated type valves (they are not ON-OFF)

|

|

| |

Technical Specifications (Approximately) |

|

| |

| Capacity |

1/1kg 2600-2700 cartoons at each charge |

| Dimensions |

5100 x 2170 x h 2390mm |

| Weight |

2950 kg |

| Pump type and power |

CALPEDA. 7.5Kw. |

| Heat Exchanger |

ALFA LAVAL |

| PLC |

LG |

| Electrical installation and Recording Device |

SIEMENS / ABB / TELEMECANIQUE / LG |

| Valves |

SAMSON / TERMO / AYVAZ |

|

|

| |

OTHER TECCHNICAL SPECIFICATIONS:

- Isolation: Autoclave external surface is isolated with rock wool of 5 cm and upper cover is covered with SISI 304L quality stainless steel having a thickness of 0.50 mm.

- Heat Exchanger: ALFALAVAL brand M6-FGL type 56 plate.

- Autoclave is a complete with all of the necessary safety systems. The safety valve, vacum breakers, digital and mechanic pressure and temperature measurement tools etc…

- Cover pressure exists and it is controlled manually and it is controlled by the mechanic systems installed on the cover and the sensors coupled with the cover. All of measurements are taken so as to not allow operating the system and opening the cover under pressure.

- In the event of power failures, the program resumes. However, a generator may be used by the purchaser company for long power faolures (because the power system such as pump do not work). Furthermore, a power supply may be used by the purchaser company for short cycles if required.

- A filter exists at the pump output on the autoclave. But still, the purchaser company is obligated to bring water, sand, metal particles to be used in the autoclave after purifying them from other materials in order to not allow pass small particles.

- All of the equipments and materials used in the system comply with the international standards.

- Safety valve: TERMO brand spring type safety valve. 3 atm discharge set.

- Level control: AYVAZ brand MG33 magnetic type level control device.

- Record: ABB brand SM502FC type recorder, SD CARD MEMORY 512Mb. 4-channels.pressure and temperature recorder.

- Valves: Air input, water input, pressure release.SAMSON brand positioner control valve.

- PLC: LG brand PLC assemble and touchscreen (touchpad) control panel.

- Vapor consumption is 1200-1500 kg/hour approximately.

- Water consumption is 5-6 tons approximately at each charge.

|

|

| |

|

|

| |

15-MODEL OKM ARI 34100 AUTOMATIC CLIPS MACHINE |

|

| |

HYGIENIC – EASY TO CLEAN – SIMPLE TO USE |

|

| |

OKM ARI-34100 is capable of completing up to 85 clips with 65 calibres per minute. All automatic filling machines could be easily and rapidly calibrated by using two setting points. Yarn tyeing unit could be added optionally. |

|

| |

|

|

| |

- Made up of aluminum and 304 quality stainless steel.

- With safety switch.

- Equipped with apins until and operates in frequency with the filling signal.

- Semi- automatic or full- automatic operation

- Very easy and simple to use

- Entirely made up of 304 quality stainless metal,

- Hygienic.

- Extremely easy and simple to clean

- Wholly conforms to CE directives

- Very easy and simple to use.

|

|

| |

Technical Specifications |

|

| |

| Model |

Okm 34100 |

| Machine category |

Automatic clips machine |

| Capacity |

3600 |

| Engine power |

1.5 |

| Net Weight kg |

400 |

|

|

| |

Dimensions/mm |

A |

2959 MM |

B |

1697 MM |

C |

2100 MM |

|

|

|

|

| |

|

|

| |

16- MODEL ODM 100 AUTOMATIC FILLING MACHINE |

|

| |

HYGIENIC – EASY TO CLEAN – SIMPLE TO USE |

|

| |

Used in sausage, spiced sausage, salami, production. Capable of filling at the desired weight and automatically.

Equipped with a pallet system comprising of 6 pallets.

Thanks to the European vacuum system, prevents air to be trapped within the package and ensures complete filling.

- Capable of operating serially with automatic clips thanks to the communication link.t

- With lift

- Produces sausage portions rapidly thanks to the sausage apparatus.

- Capacity of 250 it. Of meat.

- With safety switch.

- Entirely made up of 304 quality stainless metal.

- Hygienic.

- Extremely easy and simple to clean.

- Wholly conforms to CE directives

- With servo-motor and touch screen.

|

|

|

|

| |

Technical Specifications |

|

| |

| Model |

Odm 1000 |

| Machine category |

Automatic clips machine |

| Capacity kg/h |

1000-1500 |

| Engine power/kw |

3.8kw-1680 rpm |

| Net Weight/ kg |

1100 |

|

|

| |

Machine Dimensions/mm |

A |

1000 MM |

B |

1860 MM |

C |

3050 MM |

D |

1030 MM |

E |

1250 MM |

|

|

|

|

| |

|

|

| |

17- MODEL ODM 200 AUTOMATIC FILLING MACHINE |

|

| |

HYGIENIC – EASY TO CLEAN – SIMPLE TO USE |

|

| |

Used in sausage, spiced sausage and salami production. Capable of filling at the desired weight and automatically. Equipped with a pallet system comprising of 6 pallets. Thanks to the European vacuum system, prevents air to be trapped within the package and ensures complete filling. |

|

| |

|

|

| |

- Capable of operating serially with automatic clips thanks to the communication link.

- With lift

- Produces sausage portions rapidly thanks to the sausage apparatus.

- Capacity of 250 it. Of meat.

- With safety switch.

- Entirely made up of 304 quality stainless metal.

- Hygienic.

- Extremely easy and simple to clean.

- Wholly conforms to CE directives

- With servo-motor and touch screen.

|

|

| |

Technical Specifications |

|

| |

| Model |

Odm2000 |

| Machine category |

Automatic clips machine |

| Capacity kg/h |

2000-3500 |

| Engine power/kw |

3.8kw-1680 rpm |

| Bowl capacity/liter |

200 |

| Vacuum Pump |

2mbar-25m3 |

| Net Weight/ kg |

1100 |

|

|

| |

|

|

| |

Technical informations |

|

| |

Dimensions/mm |

A |

1000 MM |

B |

1860 MM |

C |

3050 MM |

D |

1030 MM |

E |

1250 MM |

|

|

|

|

| |

18- CONSERVE BELT CONVEYOR |

|

| |

|

|

| |

19- CONSERVE SEAMER |

|

| |

Technical Specification

- Illustration of a mechanically operated machine used in the seaming of the top and bottom covers of a round can body with charmed edge.

- specially “stainless steel” seaming rollers – tools for food industry Cast iron body

- Head and shanks equipped with ball bearing system

- Hardened and ground parts of eccentric and cam

- Standard production using technical drawings

- Production using CNC machine tools

- Excellent results in round can and filter seaming operation

- Pneumatic pedal system on request.

|

|

|

|

| |

| Production capacity |

2400 Cans/h |

| Max. can height |

300 mm |

| Min. can height |

25 mm |

| Max. can diameter |

250 mm |

| Min. can diameter |

40 mm |

| Plate thickness |

0.2 – 0.4 mm |

| voltage Supply |

220 / 380 V 50 Hz |

| Motor power |

1.1 Kw |

| Machine Height |

1770 mm |

| Machine Width |

1000 mm |

| Machine Depth |

1000 mm |

| machine weight (Approx) |

850 Kg |

|

|

| |

|

|

| |

20- MEAT CARRIER |

|

| |

Technical Specifications |

|

| |

Type |

MEAT CARRIER Entirely made up of stainless steel |

Capacity |

200 it |

Dimensions |

580*625*595mm (w*l*h) |

Weigh |

42 kg |

|

|

|

|

| |

|

|

| |

21- OVEN TROLLEY |

|

| |

Technical Specifications |

|

| |

Type |

Oven Trolley Stainless steel. |

Capacity |

200 kg |

Dimensions |

1000*1000*1950 mm (w*l*h) |

|

|

|

|

| |

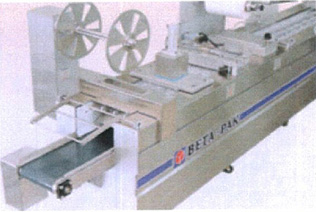

G-AUTOMATIC PACKING MACHINE BPZ 400 FULL Automatic chain vacuum thermoform packaging machine(Sausage, hotdog, salami, hen, sea products) |

|

| |

BPZ-400 is a complete packaging line in flexibility meeting various needs that carries out successive

packaging process and gains along shelf life.

It is an improved packaging system having product compliance and highly sensitizes dozing system, which realizes small scale or large scale high hygienic

packaging.Being a machine operated by a single Operator it requires minimal maintenance and works without any noise and failure. |

|

|

|

| |

All of the air inside the packaged product is vacuumed by

a specific vacuum engine in order to ensure long life of

the products. Thanks to the fact that all its mechanisms

including main chassis and feet are made of 304 quality stainless steel and sheet profiles,it is long live even in the most difficult working condition. Up-to-date materials are used in hydraulic and pneumatic line and state of the art technology applied.

Bpz-400 is a machine that is operated with 3 phase's servo

motor and in which the necessary adjustments

can be done very easily. It has a touch screen and is

Commanded with an electro pneumatic system. |

|

|

|

| |

Max foil width |

460 mm |

Max depth |

80 mm |

Reel diameter |

Base-600 mm lid-300 mm |

Reel core diameter |

76 |

Capacity |

6-8 cycle/min |

Compressed air |

6 bar, max 1200 Lt/min |

Cooling water |

12-16 c, 4100 kcal/h |

Electrical values |

Max 12 KW,380v |

Base film |

Pvc+ PE,PS+PE |

Lid film |

AL+OPP,AL |

Machine dimensions |

5000*1500*2000MM |

Max weight |

3000Kg |

|

|

|

|

| |

|

|

| |

22- SHIRINK MACHINE FOR CONSERVE |

|

| |

MAX. PACKAGE DIMESIONS 450*450*330MM

CAPACITY

9-11 PPM

REQUIRED ELECTRICITY

380V-3PH, 50-60HZ

MAX.ELECTRIC POWER

10KW

ELECTRIC CONSUMPTION

250Lt/min

WORKING PRESURE

6 bar

KNIFE SYSTEM

LAST Technology RAZOR BLADE System

SEALING TIME ADJUSTMENT

0-3 Sn.

SHRINK TUNNEL HEAT ADJUSTMENT

0-50-300 C

MAX. FILM THICKESS

0.70-200 MICRON

MAX.ROLL WIDTH

650MM.

SUITABLE FILM

PE POLietile/polyethlene |

|

|

|

| |

|

|

| |

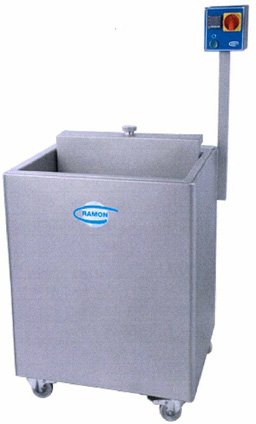

23- HOT SHRINK MACHINE FOR MEAT |

|

| |

Plat form dimension (cm) |

58*35 |

Cycle time (cycles/min.) |

3 |

Volume of water (its) |

70 |

Electrical heating (w) |

2*5400 |

Motor power (kw) |

11 |

Voltage (v) |

400 |

Net weight (kg) |

165 |

Gross weight (kg) |

185 |

Packing (cm) |

102*83*163 |

Volume (m3) |

1.37 |

|

|

|

|

| |

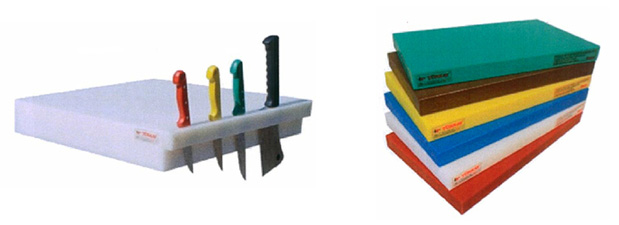

3. OTHER EQUIPMENTS FOR PRODUCTION AND BUTCHER AREA |

|

| |

NUM |

PCS |

DESCRIPTION |

1 |

1 |

MEAT PROCESSING TABLE PARTS |

2 |

15 |

SLAUGHTER HOOK FOR CATTLE |

3 |

580 |

CARRIER (DRIVER) FOR SMALL CATTLE |

4 |

245 |

SLAUGHTER HOOK FOR SMALL CATTLE |

5 |

400 |

CARRIER (DRIVER) FOR CATTLE |

6 |

100 |

CARRIER |

7 |

100 |

SLAUGHTER HOOK FOR SMALL CATTLE(SPECIAL) |

8 |

1300 |

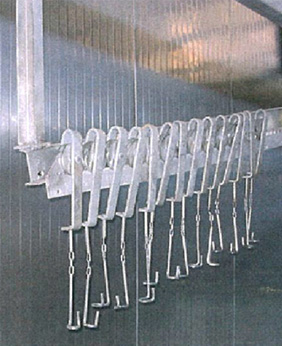

T PROFILES FOR OVEN |

9 |

1 |

EFA SB 322 E / 42 SPLITTING SAW |

10 |

1 |

EFA 57 BRISKET SAW |

11 |

1 |

EFA Z12 HYDARULIC CUTTER FOR HORNS |

12 |

1 |

EFA 620 DEHIDER KNIFE SYSTEM KNOLL |

|

|

| |

|

|

| |

1- MEAT PROCESSING TABLE PARTS

|

|

| |

|

|

| |

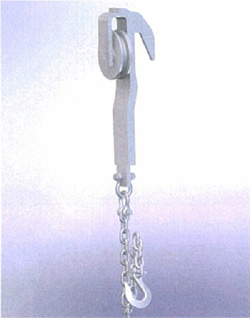

2- SLAUGHTER HOOK FOR CATTLE

|

|

| |

|

|

| |

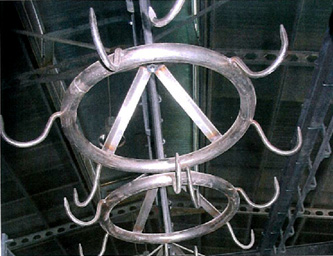

3- CARRIER (DRIVER) FOR SMALL CATTLE

|

|

| |

|

|

| |

4- SLAUGHTER HOOK FOR SMALL CATTLE

|

|

| |

|

|

| |

5- CARRIER (DRIVER) FOR CATTLE

|

|

| |

|

|

| |

6- CARRIER

|

|

| |

|

|

| |

7- SLAUGHTER HOOK FOR SMALL CATTLE (SPECIAL)

|

|

| |

|

|

| |

8- T PROFILES FOR OVEN

|

|

| |

|

|

| |

9- EFA SB 322 E / 42 SPLITTING SAW

|

|

| |

|

|

| |

10- EFA 57 BRISKET SAW

|

|

| |

|

|

| |

11- EFA Z12 HYDARULIC CUTTER FOR HORNS

|

|

| |

|

|

| |

12- EFA 620 DEHIDER KNIFE SYSTEM KNOLL

|

|

| |

|

|

| |

4- Hygiene and packing equipments |

|

| |

NUM |

PCS |

DESCRIPTION |

1 |

2 |

HYGIENE SANITATION UNIT |

2 |

10 |

ELECTRONIC INSECT KILLER (CIZZZ) |

3 |

366 |

BIC CARTON BOX |

4 |

300 |

SMALL CARTON BOX |

|

|

| |

|

|

| |

1- HYGIENE SANITATION UNIT

|

|

| |

|

|

| |

2- ELECTRONIC INSECT KILLER (CIZZZ)

|

|

| |

|

|

| |

3- BIC CARTON BOX

|

|

| |

|

|

| |

REQUIREMENTS OF PROJECT

- Must be a storage room approximately (110m2) for empty conserve.

- Must be a storage room approximately (130m2) for raw materials (casing, clips, role etc.)

- Must be container to pack products in carton boxes

- Must be a cold storage room for final product

- Must be a steam tank (capacity = 3500 m3/h) optionally

- Firstly, must be built new part for cooking and boiling area and put in machines as marked F -8-9-12-14 as shown the technical drawings.

- Otherwise if a) will not be happen, secondly solution, will build a tunnel to pass other area. Then we plan to put in machines as marked F- 8- 9- 12-14-17-18-19 as shown end of technical drawing

|

|

| |

|

|

| |

OUR REFERENCES IN TURKEY |

|

| |

AK-Et Kibris |

Ege geneti |

Krisal Restoran |

Akkoyun Gida |

Egecan ET |

Lider ET |

Alarko Alfarm |

Ekol Hipermarketler |

Lemar-kibri |

Alp Hindi |

Ekomar Hipermarketler |

yasinogullari ET |

Altin ET |

Elif ET |

Maksi marketler |

Altinkaya besyildiz |

Elif Sucuklari |

Mandali gida |

Asma hypermarket |

Emin Hayvancilik |

Maret A.S |

Atalaya Mutfak |

Emre Tavukculuk |

Martas yemek |

Ayanoglu Denizcilik |

Eray Elektronik |

Mayet |

Aydinlar Makarna |

Eregli demir celik Fabrikasi |

Mega Mutfak |

Aysa Gida |

Erenler ET |

Meridyen Magazacilik |

Besiktas Jimlastik Kulubu |

Ergeten Pastirma |

Merkez Bankasi Yemekhaneleri |

Bagdate Ocakbas |

Erimpas A.S |

MIGROS |

Bal-ET |

Ersan ET |

Mopas |

BAL-ET Urunleri |

ET Dunyasi |

Murbay |

Barcelo Otel Eresin |

Etas |

Mulsurler |

Bayak Gida |

Eti Biskuvileri |

Enfes ET |

Bayak Gida |

Fenerbahce Ordu Evi |

Onur Hipermarketleri |

Basyazici |

firat ET |

Orpa Hipermarket |

Begendik |

Fiskobirlik |

Orucoglu ET |

Bereket doner |

GaLatasray Kasabi |

Kocaeli ET Pazari |

Bey Hazir Gida |

Gamak motor |

Oz-ET |

Beyti |

Gastrodizayn |

Ozden ET |

Beyza Pilic |

Gelik Restoran |

Ozdilek alisveris Merkezi |

Bifa Biskuvi |

Genc Hipermarketler |

Ozkuruslar Hipermarketleri |

Bilintur A.S |

Gimtas |

Pak Tavuk |

Birlik Gida |

Goodyear |

Panayir Gida |

Bogazici sucuklari |

Gop Gida |

Pizza Pizza |

Bolca Hindi |

Gokada firin |

Polat Otel |

Bozlar pilic |

Gonen Devlet Hastanesi |

Real Hipermarketleri |

Bulvar sut urunleri |

Graseri Gida |

Resat Balikcilik |

Burak Besicilik |

Guclu sucuklri |

Resat Balikcilik Roche |

Hisar Gida |

Gumrukcuoglu |

komutanligi |

Sultanahmet Koftecisi |

Guret |

sarigazi ET |

Carrefour |

Gurok turizm |

saritas ET |

Ceylan Dil |

Guven Besi |

Serhat ET |

Coskun sucuklari |

Guven Turk sucuklari |

Setur A.S |

CP Kesimhaneleri |

Isvicre Hastanesi |

Sezer Otelecilik |

Cagdas Mutfak |

Hacioglu Lahmacunlari |

Swiss otel |

Cagri Hipermarketleri |

Hakmar Hipermarketleri |

Salvarli ET Tum subeler |

Cekmece ET |

Hamitabat koop |

Seker Gida |

Cetinkaya Magazalari |

Hatipogli Hipermarketleri |

Tansas Magazalari |

Cetinkaya ET |

Kardelen Alisveris Merkez |

Tat konserve |

Cicek Kasap |

Karabuk Demir Celik Fabrikasi |

Takirdag Orduevi |

Civitcioglu |

Karincalar Gida |

Tosune ET |

Dematas marketler |

Kavramoglu |

Turk Telekom |

Deva holding |

Kayalar Mutfak |

Turkyilmazlar Kasabi |

Dome hotel-kibris |

Kebir sut |

Titiz ET |

Duzet A.S |

Kese Gida |

Uyum Hipermarketler |

Kiler Hipermarketleri |

kip-Et-Kibris |

Unluer |

|

|

| |

|

|

| |

OUR INTERNATIONAL REFERENCES |

|

| |

Seval meat Belgium |

Kaplan doner kebab Germany |

Sartep nazim Iraq |

Melita meat Belgium |

Hicret mulit food Denmark |

Tan bag Iraq |

Barkad kyrgyaystan |

Al yarmouk Syria |

Fetas Syria |

AK ET Cyprus Smp England |

Kib-Et Cyprus |

palar trading England |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|