| |

| |

Pasteurization system |

|

| |

|

|

| |

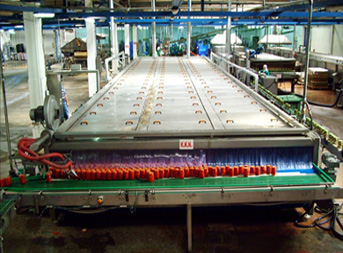

Pasteurisation / cooling tunnel |

|

| |

- 12 to 300 m² process area

- Stainless steel construction

- 6 process zones

- ± 0,5°C pasteurisation temp. sensitivity

- 15” touchscreen display

- PLC system

- Remote controlled overseas service

- Log recording and report print

|

|

|

|

| |

|

|

| |

12 to 300 m² process area |

|

| |

On sight welding flexibility gives us the possibility to manufature in slices,limited by container size.

Customer is able to see and follow the steps of installation where the machine operator starts learnin. |

|

|

|

| |

|

|

| |

Stainless steel construction |

|

| |

All construction material is AISI 304 quality stainless steel except:

- Electric motors

- Gear boxes

- Feed – discharge conveyor chains

- Mattress and sprockets

- Cables,electric and electronic components

- Tunnel conveyor bearings and housings

- Food grade UHMW-PE components

- PP spray nozzle clamps

- Rockwool insulation material

|

|

|

|

| |

|

|

| |

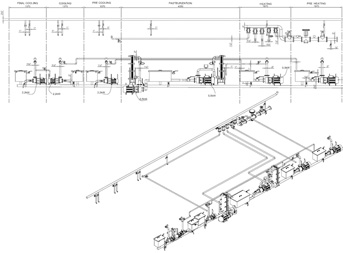

6 process zones |

|

| |

- Pre-heating

- Heating

- Pasteurization

- Pre-cooling

- Cooling

- Final cooling

Heating and pasteurization zones are 40mm rockwoll insulated |

|

|

|

| |

|

|

| |

Set temperature accuracy |

|

| |

High quality control equipment provides extreme accuracy for process temperature control. |

|

|

|

| |

|

|

| |

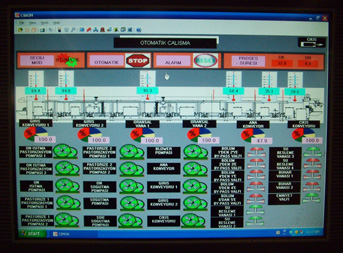

15” touchscreen display |

|

| |

On screen drawing is an easy to use interface which leads the machine operator easily in order to take necessary actions and to follow the process

. |

|

|

|

| |

|

|

| |

PLC system |

|

| |

Cimon PLC system is standart where Siemens S7-300 is optional.

IP66 Stainless steel electrical control box w/Schneider Electric components. |

|

|

|

| |

|

|

| |

Acces,support and manage devices anytime,anywhere by remote control |

|

| |

Supplied internet conection to electrical control box gives us a great flexibility for any service requirement by logging on in minutes and to the customer as well to check their operation fm anywhere of the world. |

|

|

|

| |

|

|

| |

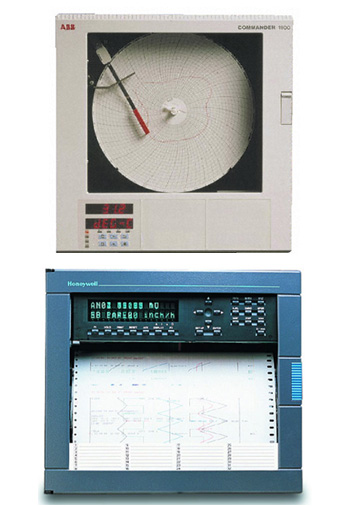

Data recording and reports |

|

| |

Log regording is supplied in process computer as standart and in Ms Excell format but also conventional chart recorders are available as optional. |

|

|

|

| |

|

|