| |

| |

Beverage production line |

|

| |

|

| |

Washing Systems

Filling Systems

Closing Systems

Labeling Systems

Conveyor Systems |

| |

|

| |

Production Plant

In order to keep quality of our products at a markedly high level, we invest in the modernization of our production plant a regular basis. The years of experience have taught us to overcome the hesitation of putting large amounts of funds into capital goods. We believe in the progress (evolution) of our production.

MAN MACHINE has at its disposal of manufacturing plant spread on a total area of over 15 000 square meters. For the purpose of metalworking we have in our factory assembly building under the direct control of quality-responsible staff. The design , management, and administrative teams are situated in a modern administrative building in direct connection with the production staff of the company.

Application Sectors

Machines and technological lines for canning industry, including lines for filling of foods, ketchup, mustard, mayonnaise, edible oil, jams, honey.

Ultra clean bottling lines on weight and flown meter dosing principle, for potting of milk , milk products natural juices and water.

Bottling lines wine and alcohol.

Bottling lines for cosmetic products and detergents.

Blotting lines for motor oils. |

| |

|

| |

Washing Systems IND-RINSERS

MAN MACHINE manufactures machines for rinsing and drying of glass and plastic containers.

Depending on the concrete application we offer liners and rotary rinsing machines that work with various combinations of rinsing solutions-water, ozone water, hydrogen peroxide solution, sterile air, hot air, steam.

For moderate capacities, under 6000 containers/hour, in conserved food factories, a very good solution is the IND-Wash 52 rinsing machines. It comprises a loading rotating table, variable speed handling device and turn-and-rinse device.

The turning of the containers if done by a tunnel with low-friction long-life Teflon guides.

After turning with the throat down, the containers are sprayed with a jet of water, or steam and are then turned again to heir normal position before exiting the machine on the outlet conveyor.

For higher capacities, 4000 to 12000 containers/hour and when a large variety of containers types and shapes is used in the factory, we offer our universal linear gripping rinsing machine model IND-Wash 56.

It can be very easily adjusted for option with different containers. It capable to work with cylindrical, flat and polyhedral containers with volumes ranging from 0.12 to 1.7 liters in its standard edition of this machine can work with containers up to 3 liters.

For glass and plastic bottles we have designed and supply rotary machines from the IND-Wash 55 series. It comprises machines with different size – with 9 to 60 rinsing valves – that correspond to capacities from 1000 to 20 bph. Depending on concrete application and product technology requirements the machines apply single or double treatment with stationary nozzles or with nozzles sinking into the container.

When higher requirements to container cleanness are applicable and they have to be sterile, the machines from the IND-Wash 55 series as supplied with various additional devices-for ozone treatment- the IND-OZ series, for hydrogen peroxide solution creation-IND-HOS, for sterile water preparation- IND-SWS.

By using rinses from the IND-Wash 55 series in double rinsing columm combination allowing great increase in rinsing times and using hydrogen peroxide and sterile water, we achieve sterilization level of up to log 5.

For water sensitive products like edible oils, mayonnaise and others the containers must be completely dry after cleaning. For such products we apply dry rinsing technology for the PET and HDPE containers, by spraying them with filtered air. For glass and metal containers we apply drying and sterilization after rinsing using our hot sterile air device IND-Blow 86 |

| |

|

| |

Washing Solutions |

| |

|

| |

IND-Wash 55 RR

Rotary rinsing machines with single or double treatment and air- blowing. |

| |

|

| |

IND-CIP S3

System for automatic preparation of rinsing and solutions. |

| |

|

| |

IND-Wash 56

Linear gripper-type washing machine suitable for treatment of containers with irregular shape. |

| |

|

| |

IND-Wash 52

Linear rinsing machine with tunnels for container overturning. |

| |

|

| |

Filling Systems IND-DOSERS |

| |

INDEX-6 offers the best solution for products with various behavior during filling. We have developed know-how for many different dosing and filling methods. For foamy, dense, aroma-rich, highly alcoholic, micriologically sensitive, ESL and particles containing products we have specialized in :

-Volumetric dosing and piston filling. For filling of dense products and foamy products. A classic technology comprising a cylinder, a piston and a three-way valve. The cylinders are made from steel AISI 4571TT and have hard and mirror-polished internal surface. The piston seals correspond to FDA, 3-A and EU machinery Directive requirements. The three-way valves are with conical design, making them self-aligning for operation at temperatures between 4 ºC and 95 ºC. Our rang includes linear volumetric piston fillers with mechanical, pneumatic or servo drive from the IND-Dose 41 and 42 series, as well as rotary volumetric piston fillers from the IND-Dose 38 RP series.

Capacity: 1.000 to 24.000 bph

-Electronic control dosing using weight sensor or flow meters. For perfect accuracy and high capacity filling of a large variety of products.

For specific products and containers for which filling with no contact between the container and the filling valve is desirable we offer our experience synthesized in the weight fillers from the

IND-Dose 49 WT series and the flowmertic fillers using Electro-magnetic flow meters or coriolis flow meters from the IND-Dose 43series. The lack of moving and sealing parts like springs, seals, pistons and others prevents breaking the flow structure. Typical applications of this technology are. In the filling of microbiologically sensitive products, due to the capability for adequate washing and sterilization; in the filling of foamy products due to the laminar product flow generated by the filling valve; for edible and motor oils and for cosmetics.

Capacity: 800 to 24.000 bph |

| |

|

| |

IND-Dose 49WTS

Linear weight filler in semi automatic edition |

| |

|

| |

Connecting to CIP

|

| |

|

|

| |

IND-Dose 43 F 10

Linear flowmetic filler with 8 filling heads |

|

| |

|

|

| |

IND-Dose 42-4

Linear volumetric filler with 4 cylinders |

|

| |

|

|

| |

IND-Dose 42- 6 Servo

Linear volumetric filler with servo drive |

|

| |

|

|

| |

Filling Systems IND-DOSERS |

|

| |

INDEX-6 offer wide range rotary filling machine for foamy, dense, aroma-rich, highly alcoholic, microbiologically sensitive, ESL and particles containing products:

-Level dosing and filling with low vacuum. For filling of liquid and homogenous products like water, wine, sprits, juices.

The machines from the IND-Dose 46 LV series use a special filling valve that seals the container through, carries out de-aeration and fills the bottle with product. Moderate dry vacuum is used to allow faster filling and suck out air bubbles and foam.

Capacity: 1.200 to 18.000 bph

-Level dosing and filling with vacuum. For filling of dense homogenous products in glass or metal containers or toppings/brine in already filled containers.

For such products we use IND-Dose 47 HV with a special valve that seals the container and links it to group of high- vacuum tank, vacuum pump with water ring for high vacuum (up to – 0.9 bar) and screw pump for returning of excessive product to the product tank. The result is excellent de-aeration of the container and rapid homogenous filling with product or topping

Capacity: 2000 to 18.000 bph |

|

| |

|

|

| |

IND-Dose 47-HV

Rotary high-vacuum filler for dense homogenous products and stews. Dosing by level. |

|

| |

|

|

| |

Multibloc systems |

|

| |

Asset clean 49 RWTC 40/30/10

For the purpose of filling of microbiologically sensitive products INDX-6 manufactures a synchrobloc Asset clean 49 for weight dosing and Asset clean 43 for flow metric dosing. Both synchroblocs are equipped with all the necessary systems for container and cap sterilization for sterilization of the machine it self-product tank , filling valves, machine clean chamber –as well as a device for generation and supply of a laminar flow of sterile into the machine working zone.

They are designed for cold filling of milk, drinking yoghurts, juices, teas, ketchup without preservatives, water and others. The machines comprise one or two bottles sterilization turrets, filling section utilizing a special, electronically controlled filling valve for laminar flow no contact filling and a capping turret with magnetic capping heads and a linear rinser for caps sterilization.

Capacity: 2000 to 22.000 bph |

|

| |

|

|

| |

Asset clean 49 RWTC 30/40/30/10

Pragmatic 49 Weight Tech

Weight filling Tribloc

Pragmatic 48 RRCC

Multibloc for volumetric dosing of cognac |

|

| |

|

|

| |

Pragmatic 44 PC

Multibloc for filling of motor oil in metal boxes. |

|

| |

|

|

| |

Pragmatic 46 RR LVC

Tribloc for level filling of water, wine and alcohol. |

|

| |

|

|

| |

Closing Systems IND-CLOSERS |

|

| |

For the large variety of closure type used for the different products in the food, beverage and chemical industry INDEX-6 manufactures and supplies a wide range of closing machines, including:

Twist-Off cappers. For glass bottles and jars.

Our Twist-Off capping range includes automatic machines from the IND-Closing 14 and IND-Closing 12 series using disc –type or belt-type closing mechanism. We have different cap feeding mechanisms allowing us to offer solutions for capacity range of up to 18000 bph.

Motorized adjustment and electronic synchronization of speeds.

The IND-Closing 12 system can work with both Twist-Off and press-Twist caps.

For low capacity purposes we offer the semi automatic The IND-Closing 16 which uses dry vacuum.

To verify the vacuum generation after closing we offer testing machines IND-Test 61 and IND-Test 61 S with capacities up to 8.000 bph and up to 18.000 bph correspondingly. Vacuum measurement is performed indirectly by contact or no-contact measurement of the cap slump. |

|

| |

|

|

| |

IND-Close 14 M

Capacity up to 5.000 pcs/hour |

|

| |

|

|

| |

IND-Close 14 E

Capacity up to 8.000 pcs/hour |

|

| |

|

|

| |

IND-Close 12 E

Capacity up to 18000 pcs/hour |

|

| |

|

|

| |

Closing Systems IND-CLOSERS |

|

| |

Screw cap cappers. Appling plastic pre-threaded screw cap on glass and plastic bottles.

For plastic screw caps we use our closing machines from the IND-Close 11 and IND-Close 22 series equipped with magnetic capping heads using hysteresis technology and a pick &place device.

They allow for precise adjustment of the closing torque which guarantees a combination of secure closure and easy oppning. Different number of closing heads are used for the different capacity equipments.

-Click-cap cappers. For application of press-on (click) caps on plastic bootles.

For application of press-on (click) caps on plastic bootles.

For application of press-on caps on bottles or buckets IND-6 offers the closing machines from the IND-Close 11 and IND-Close 22 series equipped with a press-on closing head with grip end piece.

-Pilfer-Proof cappers. For closing with aluminum R.O.P.P. caps

For the various types of pilfer-proof aluminum caps available on the market we offer our closing machines from the IND-Close 11PP and IND-Close 22 PP series They use threading heads with independently adjustable rollers. Deferent number of closing heads is used depending on the capacity equipments.

The single headed IND-Close 11PP can be manufactured in multi cap edition allowing it to handle both R.O.P.P. caps and T-plugs.

-Corking machines. For application of natural and synthetic corks.

For closing with cork pugs the machines from the IND-Close 11 cork and IND-Close 22 cork series are Avery good solution. They use single or multiple closing heads with a removable four-jaw crok-shrinking instrument. Features like crok dust cleaning and inert gas injection are available.

-Special purpose machines.

For same non-standard closure needs we have designed and supply the closing system IND-Close 18. it comprises a device for application and sealing for an aluminum foil cap on the container throat and a subsequent closure device for press-on or screw caps. |

|

| |

|

|

| |

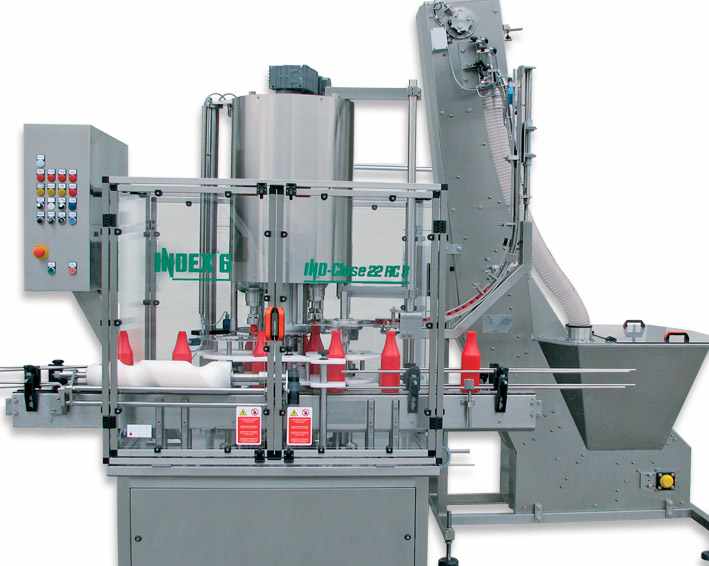

IND-Close 22 RC 4

Rotary capping machine for screw caps with positive gripping jaws. |

|

| |

|

|

| |

IND-Close 22 RC 6

With Linear cap feeder-elevator, magnetic capping heads, controllable gripping jaws and pick and place. |

|

| |

|

|

| |

Labeling Systems IND-LABELERS |

|

| |

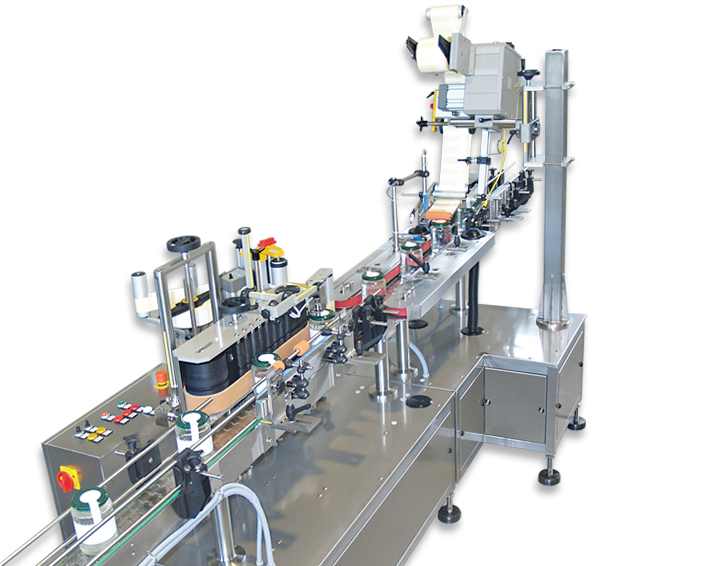

Having the most accurately placed labels and absolutely reliable application are obligatory conditions regardless of the label types and the capacity that you require for your products.

INDEX-6 has developed various automatic labeling machines and complete turnkey label packaging systems that use different types of labeling technology utilizing a different number of labeling stations and guaranteeing an application that renders label inspection needless.

The labeling machine of INDEX-6 are capable to work with paper, polyethylene and other saturated or transparent labels and all types of glass, PET,HDPE,PP and tin containers. For our turnkey solutions we offer hot glue labeling machines foe roll-fed and pre-cut labels, cold glue labelers, self-adhesive labelers, sleeve labeling machines and capsules applicators.

The machines from series IND-Lab 31, IND-Lab 32, IND-Lab 33, IND-Lab 34, are linear pressure sensitive labelers that provide surface labeling of flat, flask, cylindrical and conical containers with medium and medium-high capacity and application complexity. They are designed to apply self-adhesive labels on the front and back, wrap-around labels, collars, L and U type tamper evident labels and excise labels. The machines from the IND-Lab 36, series are rotary labelers with appreciable labeling power, providing high performance and high positioning accuracy even for complex container shapes, labels positions and label combinations.

The IND-Lab 36, series comprises machines for application of thermo-shrinkable labels and steam tunnels for shrinking of the labels. Our sleevers work with full-body sleeve, partial sleeve and tamper-evident thermo-shrinkable label. The steam tunnels use up to five different temperature sections allowing graduate labels shrinking and accurate shapes following.

For capsules on the bottle neck INDEX-6 offers the machines from series IND-Caps 84 which provide application of thermo-shrinkable capsules and rolling of poly-laminated capsules, both on one and the same machine. |

|

| |

|

|

| |

IND-Lab 31

|

|

| |

|

|

| |

IND-Lab 32

|

|

| |

|

|

| |

IND-Lab 32B

|

|

| |

|

|

| |

IND-Lab 36/9-3 ADE

|

|

| |

|

|

| |

IND-Lab 38 Sleeve

|

|

| |

|

|

| |

Conveyor Systems IND-CONVEYORS |

|

| |

Conveyors, butter systems, auxiliary equipment

To provide containers conveyance between the separate technological processes like bottle blow-moulding, depolarizing, rinsing, filling, closing, labeling, group-packing and palletizing, INDEA-6 produces and supplies integral solutions from the IND-Trans series.

-Air conveyors from the IND-Trans 71 Aero series – for transportation of PET and HDEP bottles.

-Plate conveyors – straight or turning, with stainless steel or plastic plates, from the IND-Trans 71 series- for transportation of glass, plastic and metal containers.

-Butter systems – multi-lane straight and turning conveyors with precise speed regulation from the

IND-Trans 72 series, securing smooth and continuous line operation and minimal downtime.

-Loading and unloading rotating tables from the IND-Trans 73 series for easy loading/unloading of lines with no blowing and group-packing.

-Rejection devices for automatic separation of the good from the non-good production, based on various criteria such as weight, vacuum and others.

|

|

| |

|

|

| |

|

|

|

|